Workshop 12

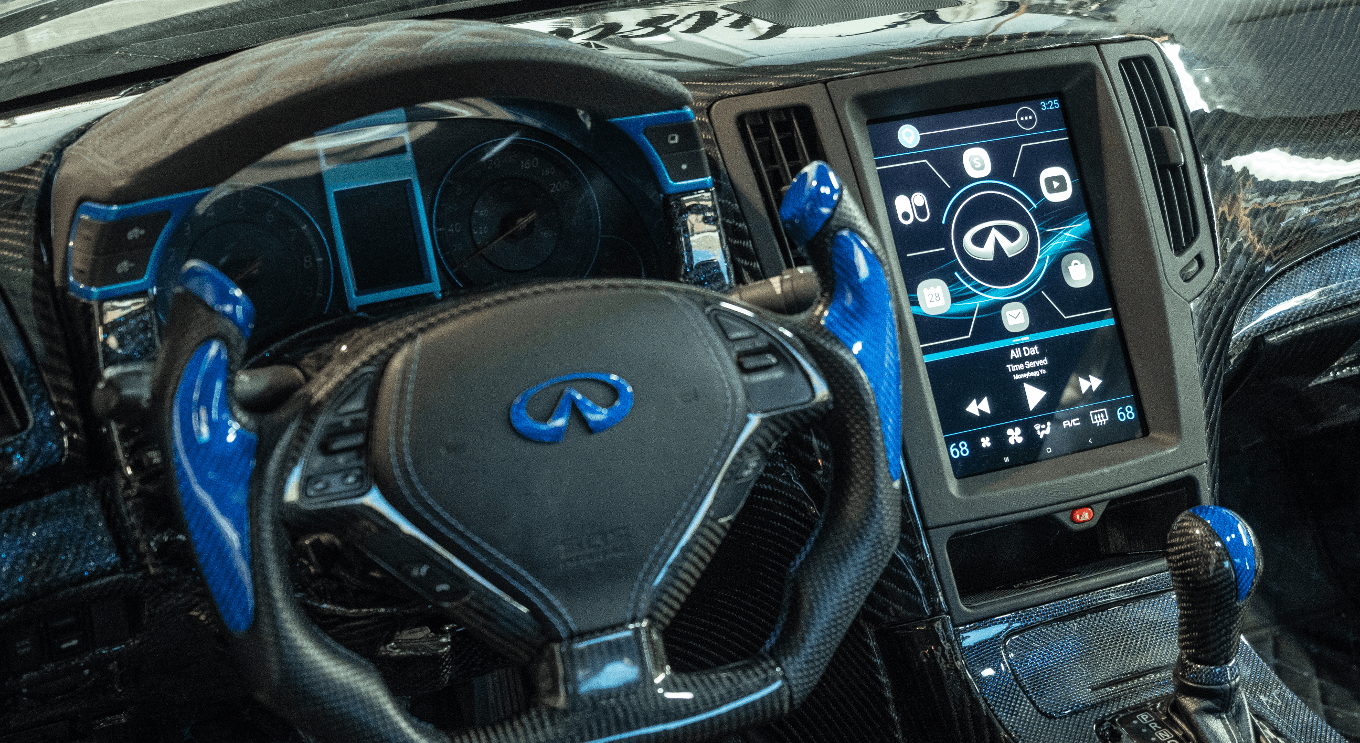

Brainiac MK2 G37 Plastics

FINAL RELEASE OF THE G37 COMING SOON

NOTE: Climate Control for the G37 is currently not available. It will be offered as an upgrade once it's ready.

Kits are manufactured on-demand. Workshop 12 manufactures some components in-house and also outsources printing of the driver-exposed plastics to Shapeways. Shapeways typically have a 3-4 week turnaround time from when an order is placed until the plastics are ready to be returned to Workshop 12.

The MK2 G37 kit includes everything you need to securely hold a Samsung Tablet (See list of available options) in your dashboard for a sleek OEM like look.

What's in the box:

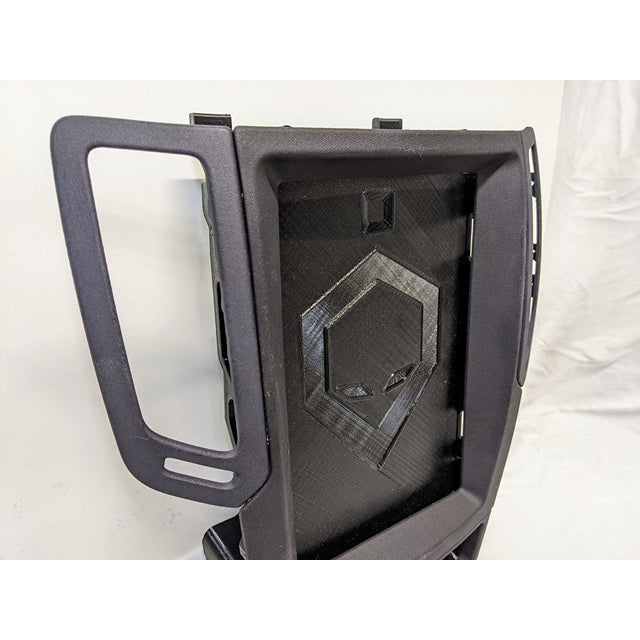

- 1 X Front magnetic tablet surround for a clean look

- 2 X Air vent surround

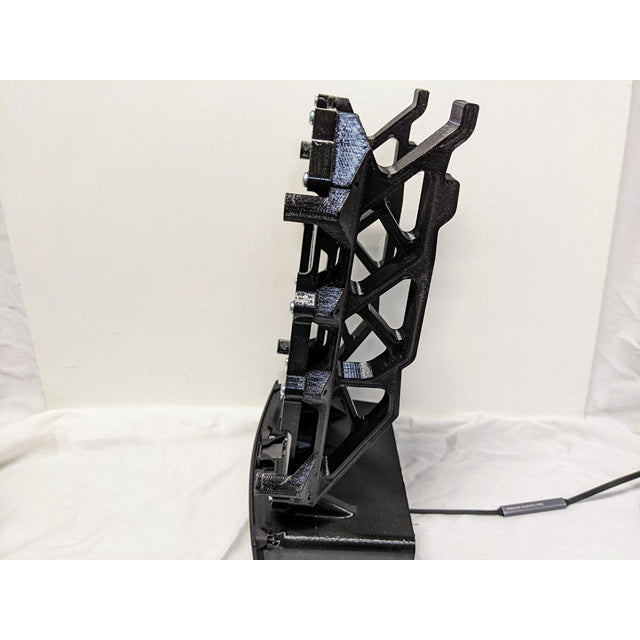

- 1 X Tablet cradle and support structure to hold your tablet securely in place

- 1 X Wireless charge pad

- 1 X Phone pocket

- 1 X Hazard switch replacement

- Assembly Screws

- Zipties for Cables

Notes:

- Plastics kit does not include stereo or climate control electronics.

-

Passenger facing surfaces are dyed black and are 3D printed nylon that we highly recommend sanding and painting to avoid UV fading of color

- Tablet is not included

Introducing MK2

We've been listening to lots of feedback since our MK1 line of products and have now produced an updated design for new vehicles. MK2 provides additional design updates complete with a sturdy magnetic face plate that allows for easy access to the tablet installed in your dashboard.

Installing Brainiac

We've pulled together a video to show the step-by-step process of installing the MK2 Brainiac plastics into your G37 which is no more difficult than performing an aftermarket stereo installation.

Supported Tablets

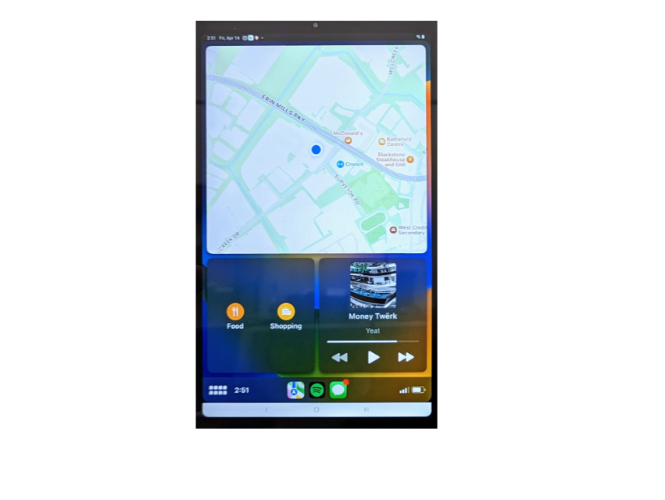

The Brainiac MK2 plastics for the Infiniti G37 have been designed to securely hold one of the following tablets in your dashboard creating a sleek factory integrated look:

Samsung Galaxy Tab A 10.5" (Model numbers T590 or T595)

Samsung Galaxy S6 10.5" (Model numbers T860 or T865)

Samsung Galaxy S6 Lite 10.4" (2020/2022 Model P610, P615/ P613, P619)

TABLET IS NOT INCLUDED IN KIT